Our growing laboratory has multiple scanning and design stations. Each station has a 3Shape scanner equipped with 5MP cameras that provide an accuracy of 7 um. The colored texture scan enables us to detect margin lines and ensure crown fitting accuracy.

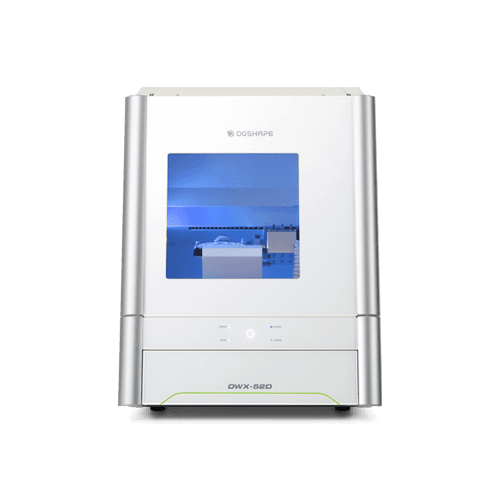

To keep up with our demanding manufacturing capacity, our milling blocks are supported by high-tech Roland DWX - 50, DWX - 51 and DWX-52 milling machines. Each unit can accurately mill in 5-axis and ensures the integrity of the zirconia crown is not compromised.

We accept cases through iTero web portal. It allows us to identify and inspect digital scans prior to model manufacturing. While models are being manufactured, we utilize the time designing restorations to increase efficiency and minimize delays.

Any clinician using a Trios Intraoral Scanner can easily submit their cases and scans to our lab through 3Shape Communicate Inbox. We can directly accept them on our 3Shape software allowing a seamless flow of production.

As traditional impressions begin to age, 3D printing has taken on an important role in the dental industry. Nowadays, 3D printers are able to print crown and bridge models with definite margin accuracy as well as 3D designed night guards. Form 3B is an exclusive dental printer that follows Health Canada Guidelines.

Ivoclar Vivadent takes their Programat furnace line to the next level with the addition of the S1 1600 sintering furnace that enables higher sintering temperatures up to 1600 degrees for beautiful restorations with the perfect level of translucency. It features a new type of heating element specially designed for intensive everyday use. These heating elements are characterized by their long service life and even heat emission – a feature that is essential to achieve optimum sintering results. This furnace was also specifically designed in conjunction with IPS e.max® ZirCAD materials.

Nabertherm LHT 02/17 LB Speed is an industrial level sintering furnace designed and manufactured in Germany. The furnace is tailor-made to sinter specifically Zirconia. With its bottom loading mechanism allowing for a large sintering capacity by stacking Nabertherm charge staggers on top of each other. As temperature rises, the unique cylindrical furnace chamber ensures uniform heating around the staggers.

© 2021 West Coast Dental Laboratories Ltd.. All Rights Reserved | Designed By Green Apple Solutions